Sales Tel

+86-18928379199

|  |  |  |

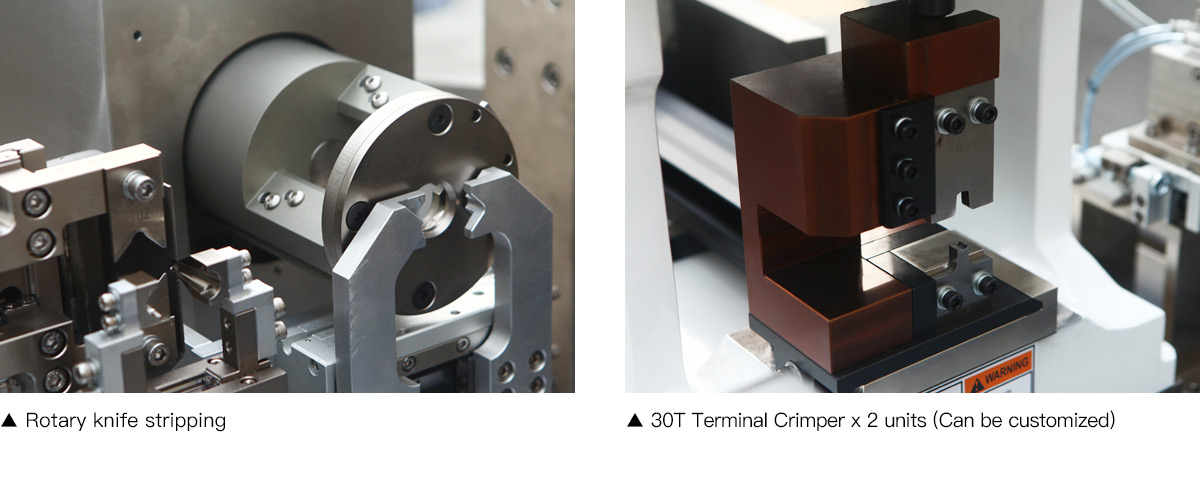

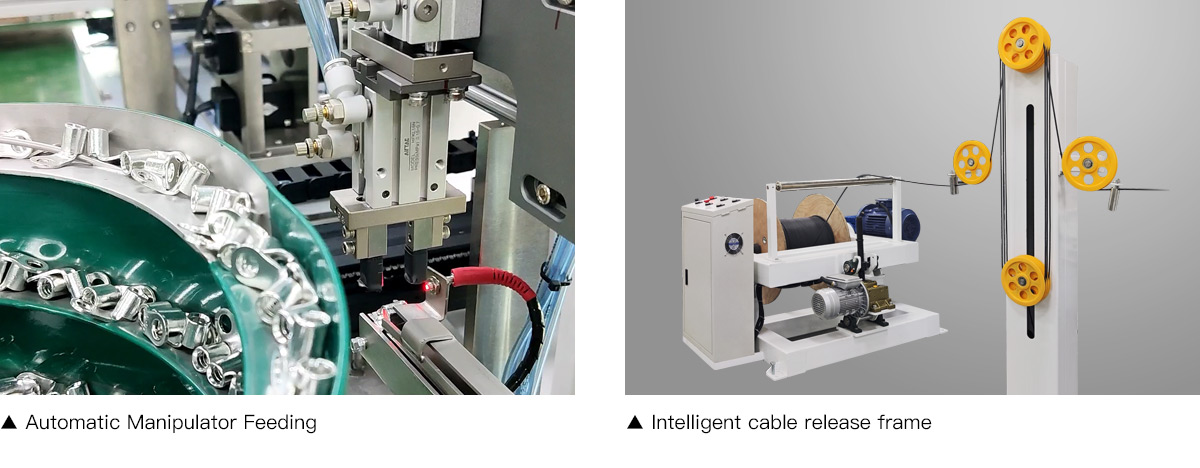

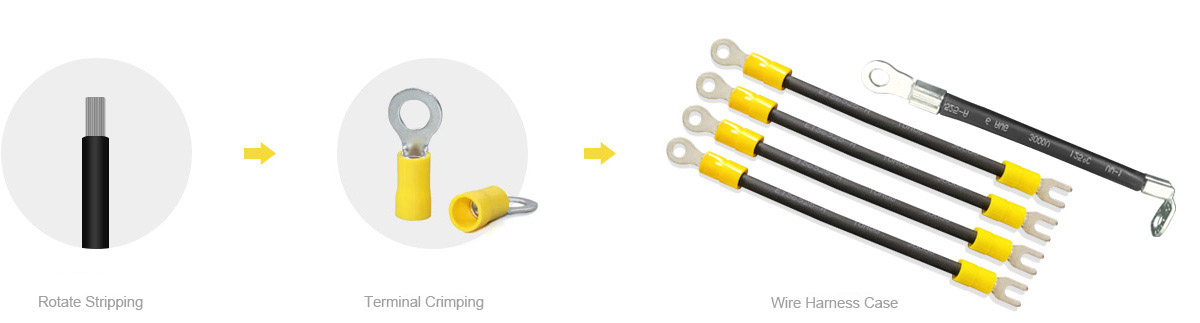

Cutting/Stripping/Dual Head Crimping/Heat Shrinkable Tube

1. The overall design and installation quality of the equipment is in line with the relevant national standards, the structure and technology is reasonable and installed in place according to the standard process. The setting is easy to operate, safe and labor-saving, and the logo is clear.

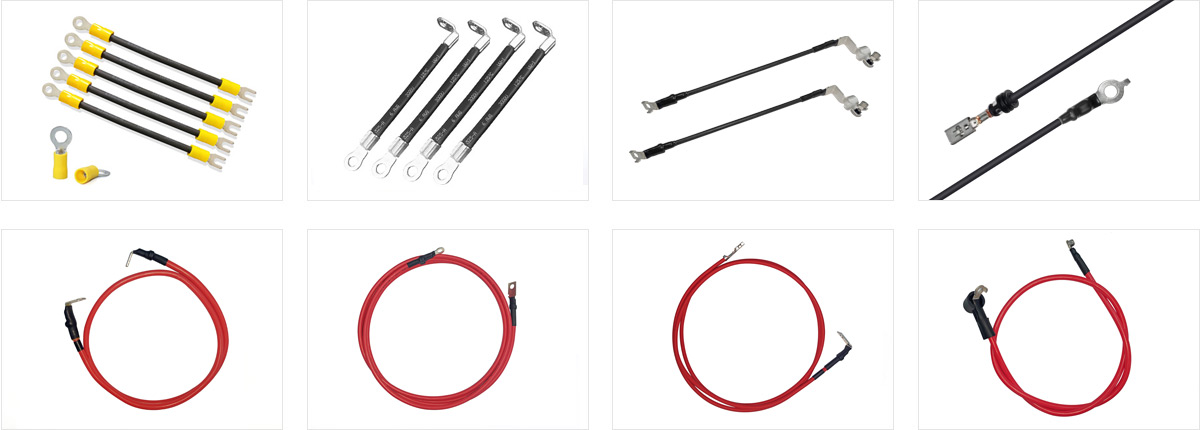

2. The finished products all meet the requirements of the drawings, and the appearance meets the requirements of customers.

3. Operator required:1 person is mainly used for feeding and can supervise 4 or 5 machines at the same time.

4. The surfaces of all parts of the equipment are electroplated and heat treated, and the machine frame is sprayed with square tube welding surface.

5. The machine is controlled by PLC and equipped with abnormal shutdown alarm function. The real-time alarm is displayed on the touch screen in real time and has the function of fault self-diagnosis.

6. The stability of product quality and the adaptability of varieties are fully considered in the design and manufacture of equipment. Open structure design is convenient for later category, type transformation and equipment technology upgrading.

7. During the operation of the equipment, there is no abnormal sound, and the smell, vibration and temperature rise meet the standard.

8. The equipment has good and comprehensive safety protection measures, and safety shields are installed in mechanical parts such as transmission belts, shafts, transmission chains, couplings and gears.

Speed: 4.5s~6s/pcs (determined by the length of the product line).

Output: 600 million 800 pounds per hour (specifically determined by the length of the product line)

|

Equipment name |

Large Square Cable Terminal Automatic Crimping Machine |

|

Function |

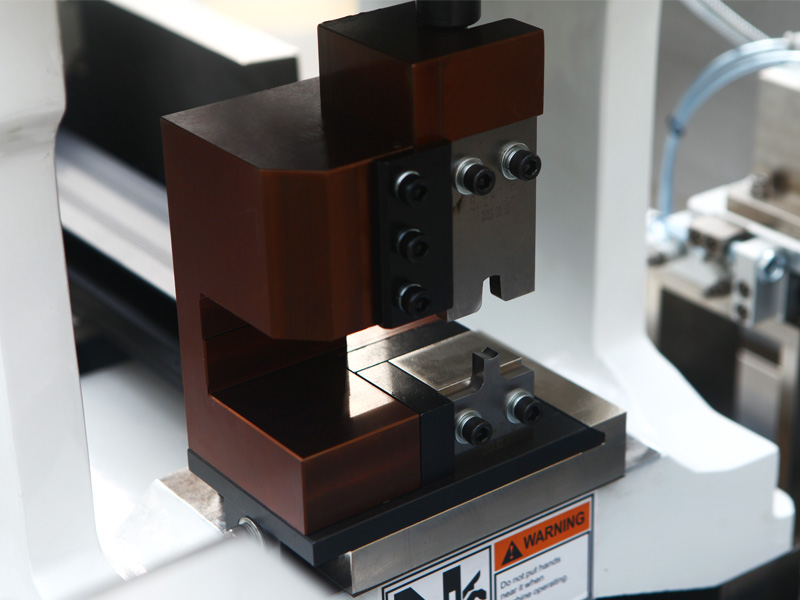

Wire cutting,stripping, double end crimping, wire direction reverse.good/bad wire selecting |

|

Wire Specification |

10AWG、12AWG /10mm2:-16mm2(customized) |

|

Wire color |

Single Color |

|

Cutting length |

50mm-1500 mm |

|

Cutting precision |

Wire length +0.5%mm |

|

Half Stripping |

3 mm-15 mm(optional) |

|

Stripping length |

0 mm- 15 mm (optional) |

|

Stripping precision |

Tolerance ±0.1mm |

|

Cutting-in precision |

Max adjustment: 2mm(Manually +0.05mm) |

|

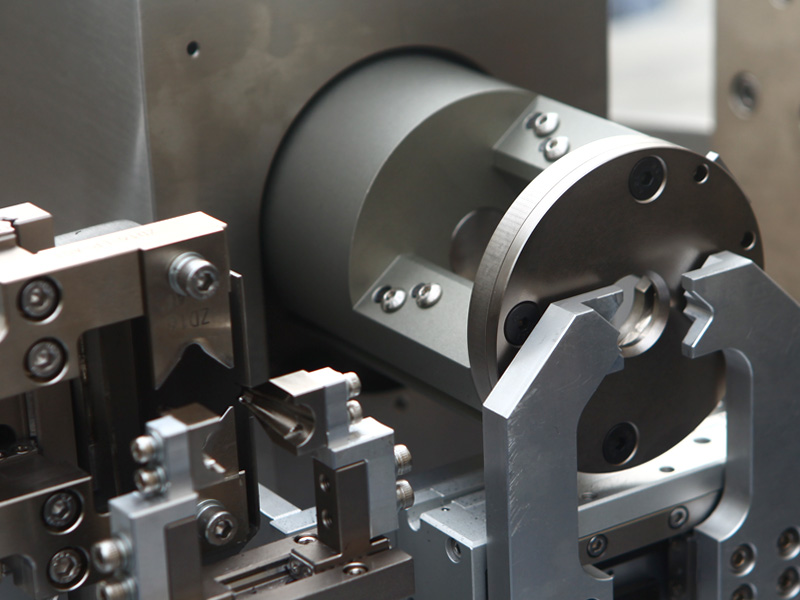

Crimper |

10T-30T servo crimper x2 units (customized) |

|

General applicator |

General applicator |

|

Detection device |

Standard configuration: low pressure, wire detection, wire overloaddetection, crimp error detection, terminal detection, terminal overoaddetection, terminal insertion detection, pressure detection device,CCDvisual inspection |

|

Control method |

PLC control system |

|

Power supply |

Single phase AC220V/240V50HZ 10A |

|

Air force |

0.5MPa、about 170N/min |

|

Temperature range |

5℃ -50℃ |

|

Size |

2000Wx1700Dx1600H(Excluding protrusions) |

|

Weight |

About 1000kg+80kg (wire release support) |