Sales Tel

+86-18928379199

|  |  |  |

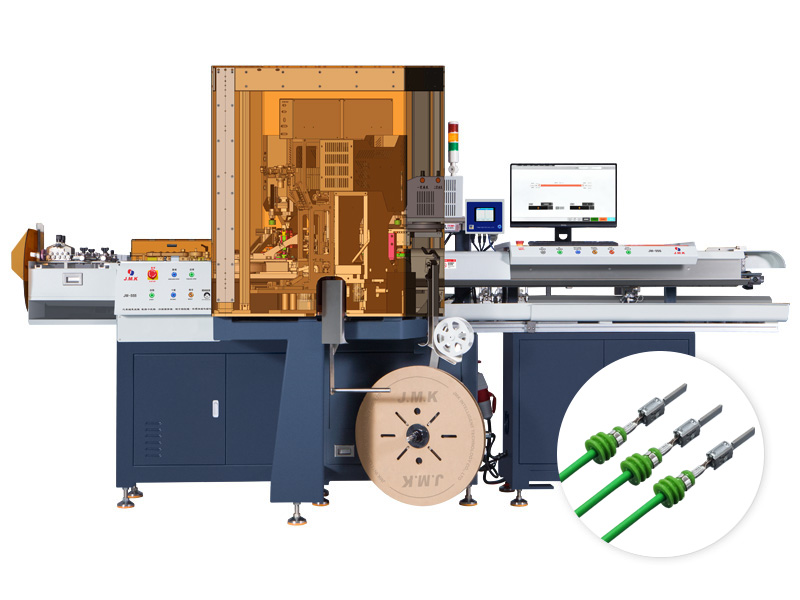

JM-555A Automatic Single/double end waterproof plug threading crimping machine

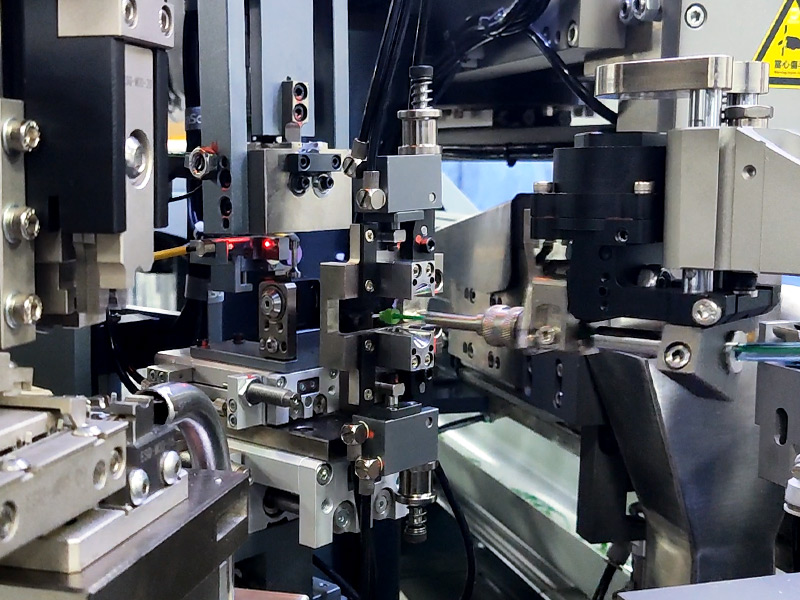

JM-555A Wire seal station

What JM-555A Automatic Crimping Machine Single/Double end Waterproof Plug Threading Crimping Machine Can Do?

JM-555A are able to do fixed-length cable/wire cutting, single/double end half-stripping or full-stripping, single/double end crimping, waterproof plug threading. And all processes can be completed synchronously.

1.International-grade design with a compact and streamlined structure;

2.Equipped with a flexible wire feeding system that protects the wire surface while ensuring high wire length accuracy;

3.Utilizes a servo-driven crimping system to guarantee stable and consistent crimping precision;

4.User-friendly PC interface with graphical display for intuitive and simplified operation;

5.Built-in pressure management system enables real-time monitoring, automatic defect detection, and removal;

6.Supports customized processing for FAKRA wire harnesses and ultra-short new energy harnesses;

|

Model |

JM-555-----JM-555A-----JM-555B Automatic Crimping Machine Single/Double end Waterproof Plug Threading Crimping Machine |

|

Power |

13KW(Max) |

|

Capacity |

1000~5200pcs/H(shortest cut wire) |

|

Gas source |

0.5-0.7MPa |

|

Air consumption |

3m/h |

|

Can cut off the length |

50-9999mm |

|

Can cut off precision |

≤1000mm,±1mm,21000mm,((1000mm+0.2%xL) |

|

Peeling length |

0.1-16mm |

|

Machinable wire diameterx2 |

0.13-6.0mm2(26-10 AWG) |

|

Send speed |

8-12m/s(Max) |

|

Crimp ability |

20KN(tonnage can be customized) |

|

Crimp travel |

30mm(40mm Optional) |

|

Ambient temperature |

0~40℃ |

| Size |

L3720xW1450xH2010mm(protection quantity lifting height about 2850mm) |

|

Weight |

About 1000kg |

|

Optional |

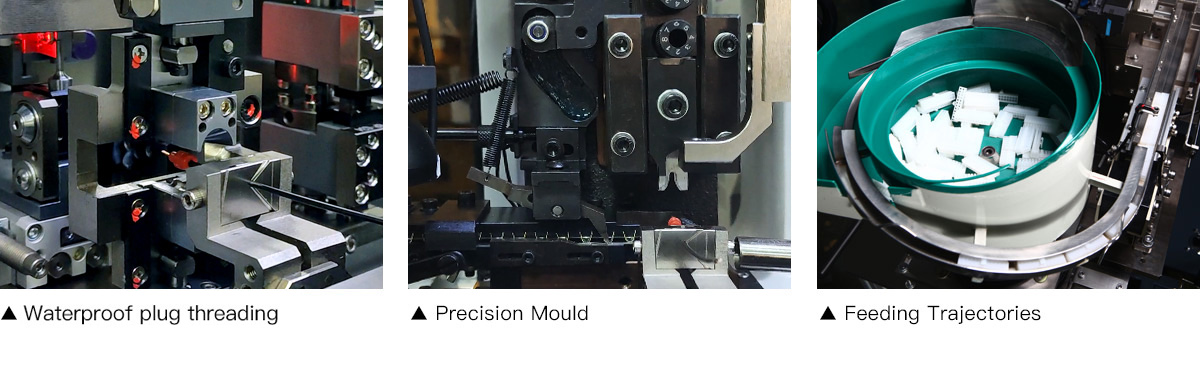

Wire seal Station; Wire Conduit Station; Visual module of crimper; Puller; Magnifying glass; Electronic micrometer; Safety cover |

Wire Harness Cases:

Wire Harness Cases:

High-Precision Automatic Crimping Machine Solutions:

Our fully automatic crimping machines deliver fast, reliable, and accurate processing of single- and multi-core cables.

From cutting to crimping and insulation, every step is automated for maximum efficiency and consistent quality.

Optional modules like crimp force monitoring, tinning, twisting, labeling, and heat shrink integration make it easy to customize your production line.