Sales Tel

+86-18928379199

|  |  |  |

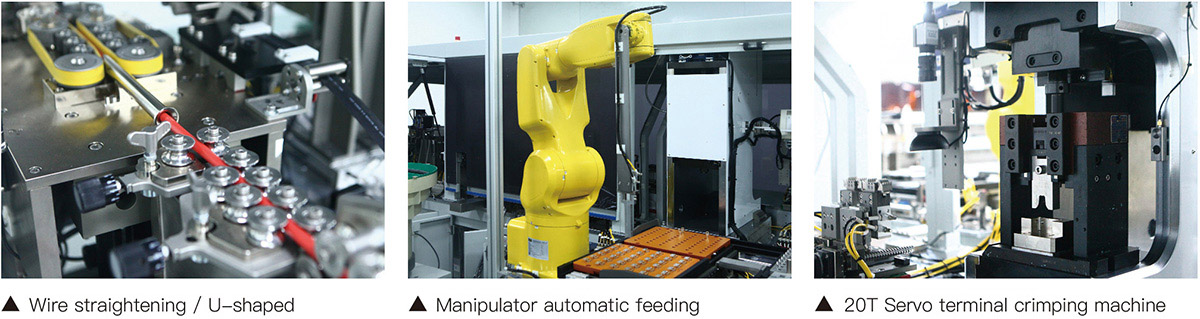

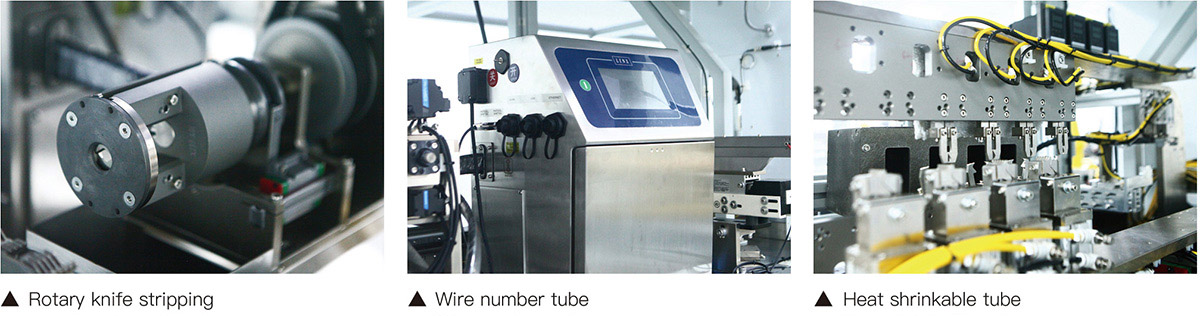

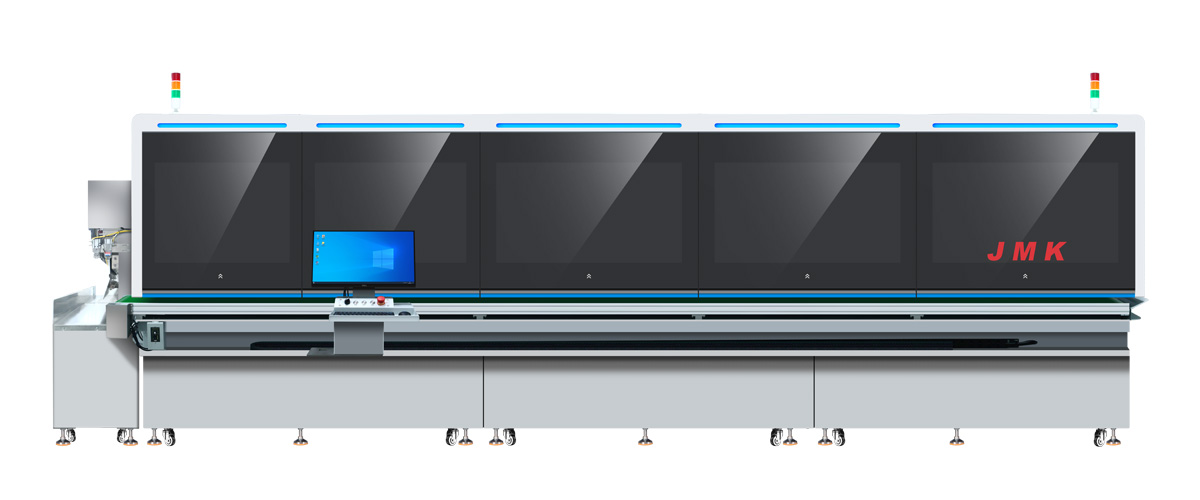

Wire Number Tube/Heat-shrink Tube/Outer-stripping/Terminals Crimping/Heat-shrink Tube Positioning/Heat Shrink

Product Feature:

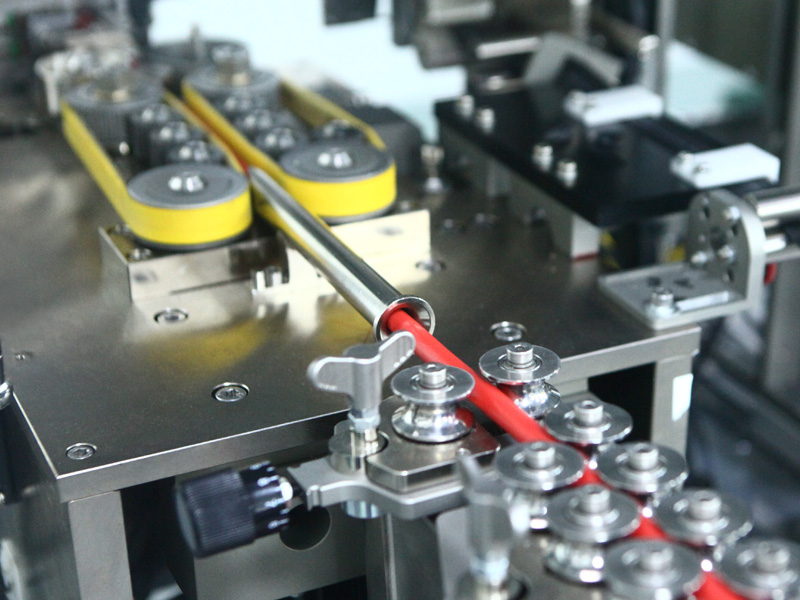

1.Features a fully closed-loop flexible wire feeding system with a rubber belt mechanism to protect the wire surface and enhance feeding accuracy.

2.Incorporates a network-driven system to meet the rigorous industrial processing demands of photovoltaic wires.

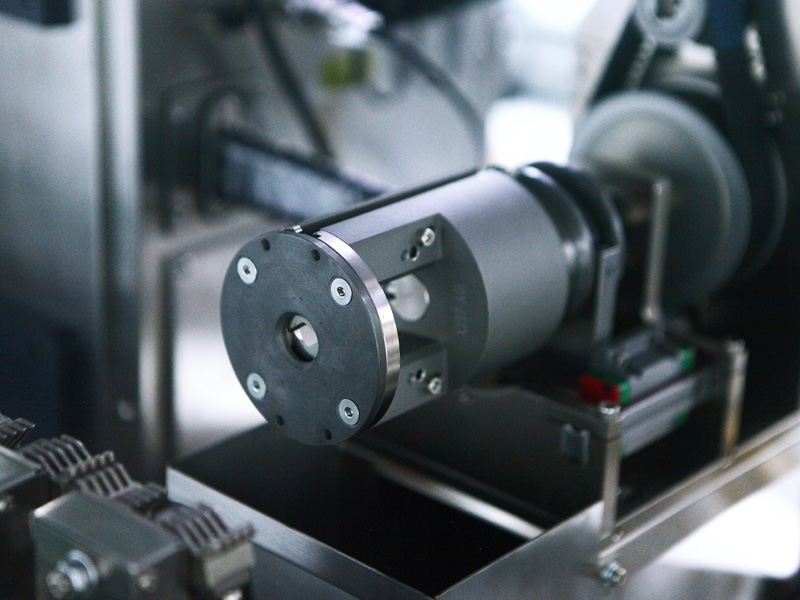

3.Utilizes imported servo motor drives to ensure high precision, efficiency, and operational stability.

4.Runs on an industrial-grade computer operating system, offering a user-friendly and intuitive interface.

5.Supports both manual and automatic debugging modes, making equipment setup faster and more efficient.

6.Equipped with a servo-driven crimping system that maintains a stable compression ratio, fully meeting cross-sectional analysis standards.

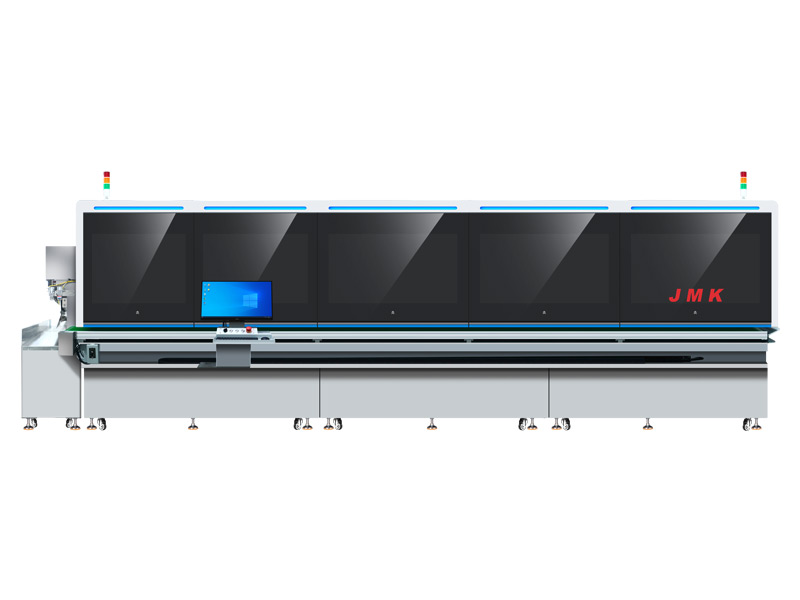

| Model |

JM-700 High voltage wire Harness production line |

|

Capacity |

Approx. 10s/pcs (at shortest tangent) |

|

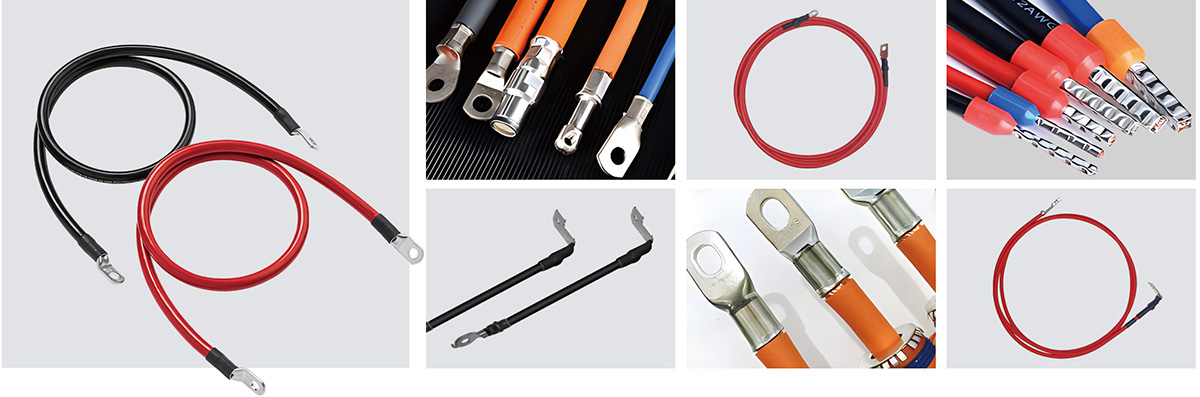

Wire range |

2.5-300mm² (customizable) |

|

Cutting length |

400mm-4000mm |

|

Stripping length |

0-20mm |

|

Cutting precision |

±0.3%xL |

|

Crimp force |

20T servo crimping machine x2 (customizable) |

|

Detecting device |

Low pressure, wire detection, pressing error; Optional: CCD visual inspection, Compression force monitoring. |

|

Control |

PLC |

|

Power supply |

AC380V 50/60Hz three-phase |

|

Aire supply |

0.5MPa, approx. 170N/min |

|

Temperature |

5°C - inner 50°C |

|

Humidity |

30%-80%RH (no condensation) |

| Size |

L6500xW5000xH1900mm (without protrusions) |

| Weight | About 6000kg |