Sales Tel

+86-18928379199

|  |  |  |

Fully Automatic Dual-head Threading and Numbering Single-head Shell Insertion Machine

JM-601B+ Full Automatic Double Head Numbering Tube Single Head Shell Inserting Machine with precision servo-driven PLC numerical control system, which can store 100 groups of recipes in order to flexibly call up production data. It can produce 60-3000mm, 1-8 wire color choices (6 colors as standard), #16 to #28 wire number production.

Main Functions:

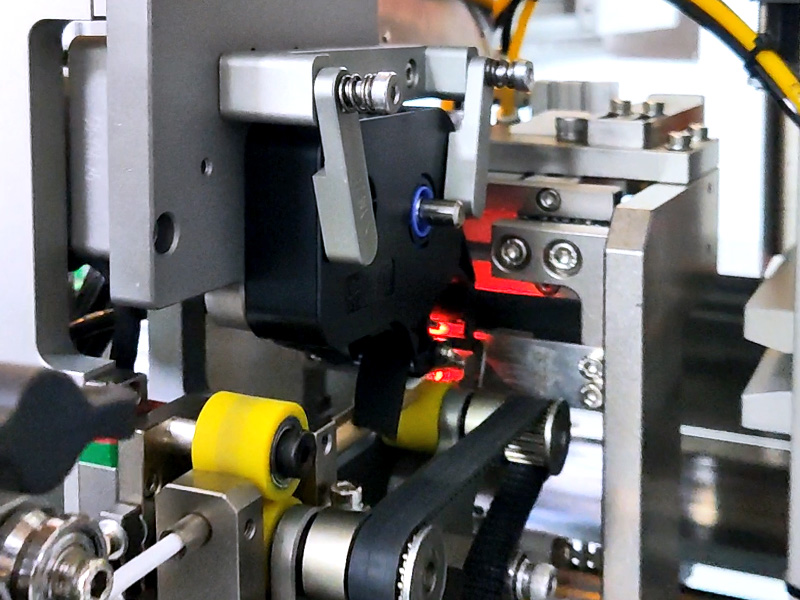

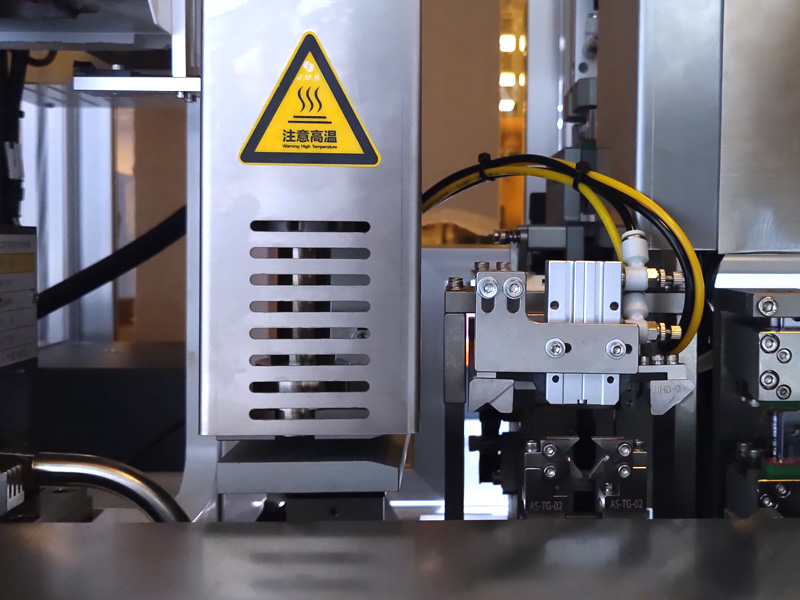

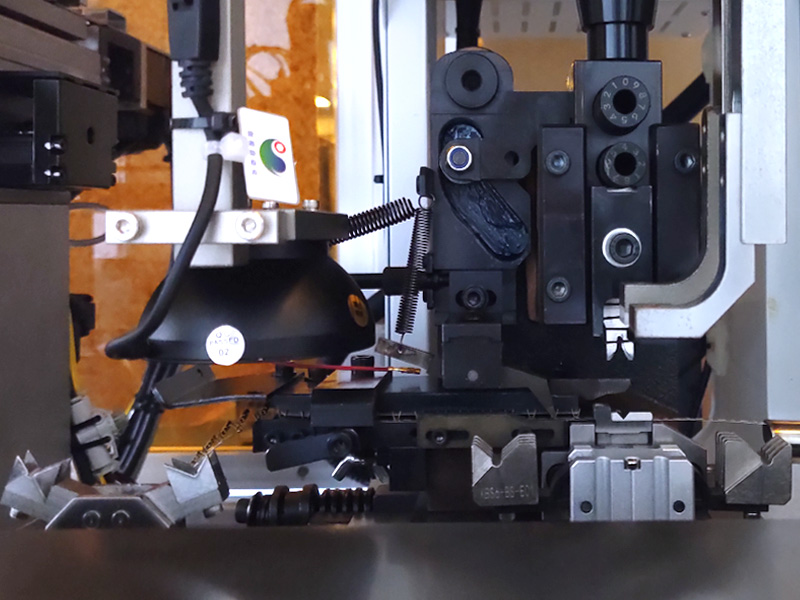

Wire cutting, tare at both ends, crimping at both ends, threading numbered tubes at both ends, heat shrinking, inserting shells at one end. Supporting non-standard customization, it can also flexibly expand many additional functions: stranding, soldering, threading waterproof pins, threading heat-shrinkable tubes and so on.

JM-601B+ can be equipped with optional pressure monitoring system and CCD visual inspection system, which can display real-time product image and crimping force curve, and conduct comparative analysis, trigger alarms when crimping defects and automatically sort out defective products, so as to monitor the quality of the whole processing process.

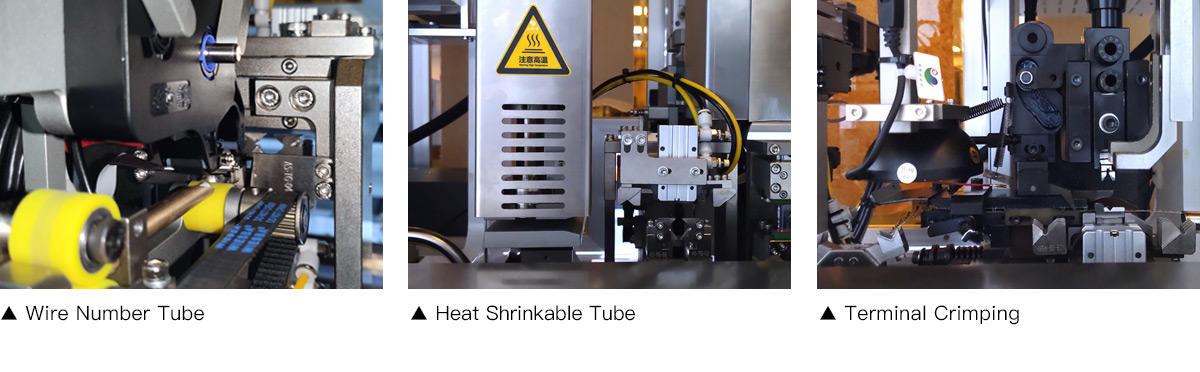

Equipment Details:

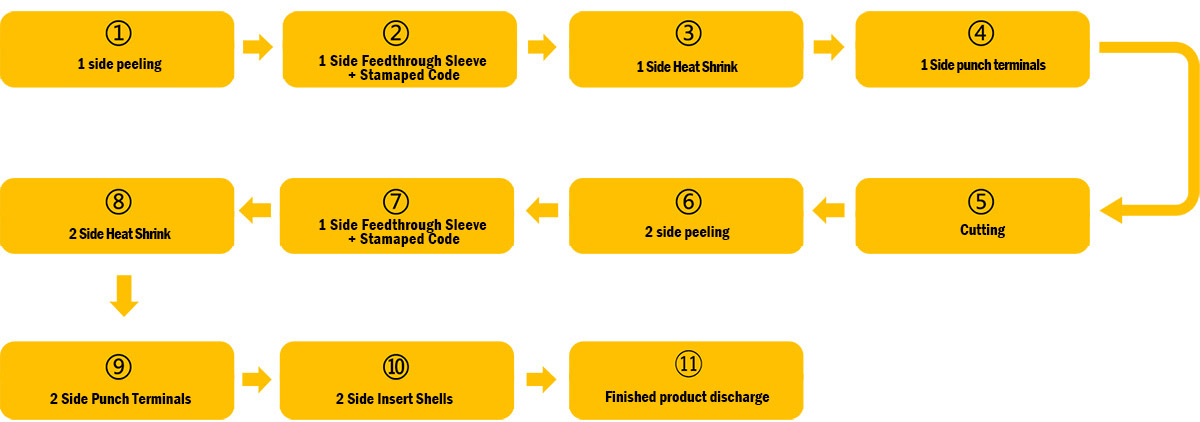

Equipment Action Flow:

Technical parameters:

| Model Name | JM-601B+ Automatic Double-head Numbering Tube Threading Single-head Shell Inserting Machine |

| Functions | Wire cutting, tare at both ends, pressing at both ends, numbered tubes at both ends, heat-shrinking, insertion at one end, reverse wire holding, and automatic sorting of good/bad goods. |

| Wire Specification | AWG#16-#28 (wire O.D. 2.5mm or less) |

| Wire Color | 6 colors (customizable) |

| Cutting Length | 60mm—3000mm |

| Cutting Length Accuracy | ±0.5%mm of product wire length |

| Stripping Length | 0-15mm |

| Pipe-Through Specification | 5mm — 25mm |

| Coding Method | Thermal transfer coding machines * 2 units |

| Crimp Strength | 2T servo press * 2 sets |

| Crimping Stroke | 30mm |

| Applicable Molds | General purpose OTP molds |

| Inspection Device |

Standard: low pressure, wire presence detection, wire overload detection, crimping error detection, terminal presence detection, terminal overload detection, terminal insertion detection Optional: pressure detection device, CCD visual inspection system |

| Control Method | PLC Control |

| Compressed Air | Not less than 5MPa (170N/min) |

| Power | Single phase AC220V 50/60Hz 16A |

| Dimension | W2000×D3000×H1600mm (excluding protrusions)+W1000+D900+H1000mm(payoff frame) |

| Machine Weight | Approx. 1000kg + 80kg (payoff frame) |

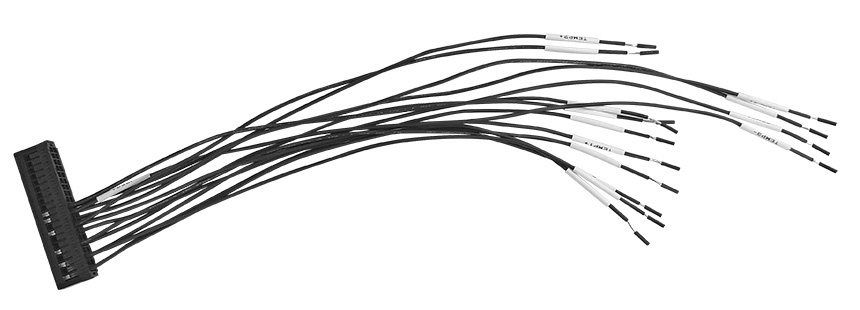

Sample wire harness: