Sales Tel

+86-18928379199

|  |  |  |

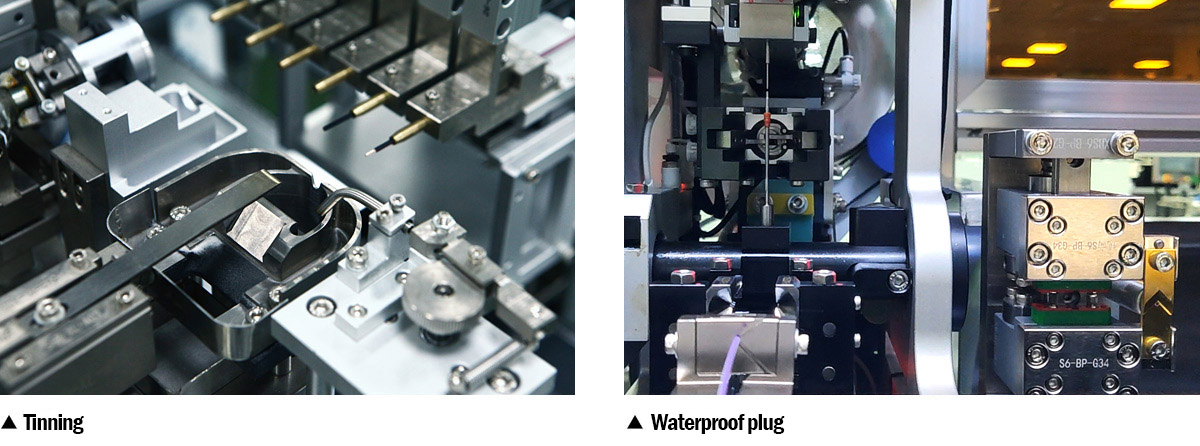

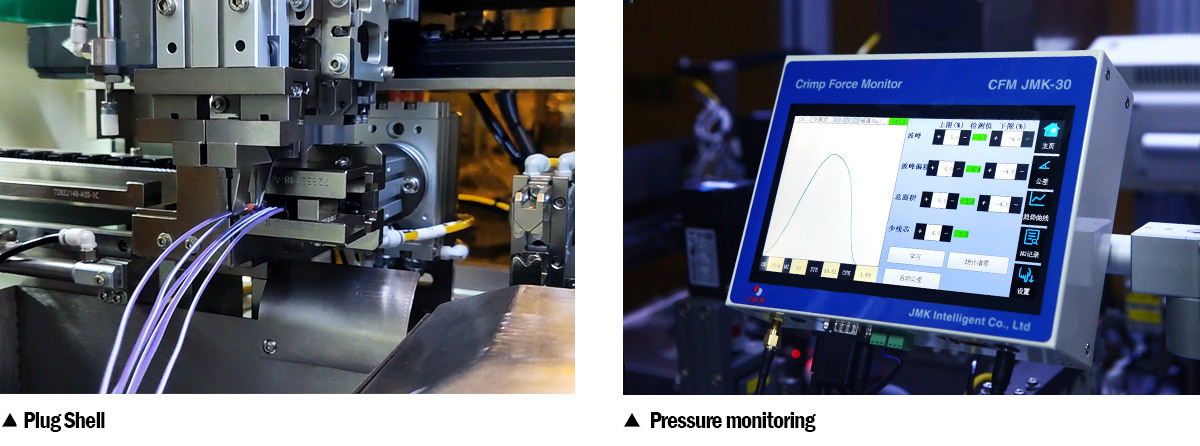

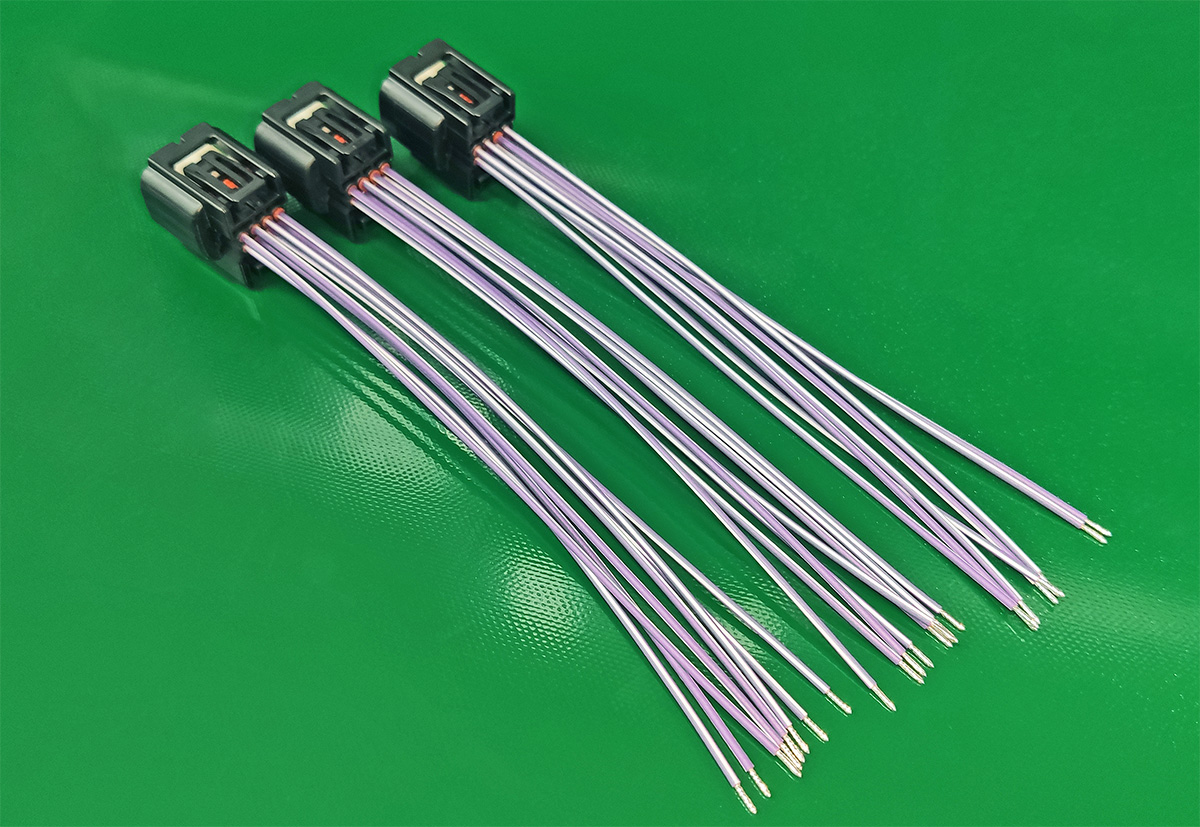

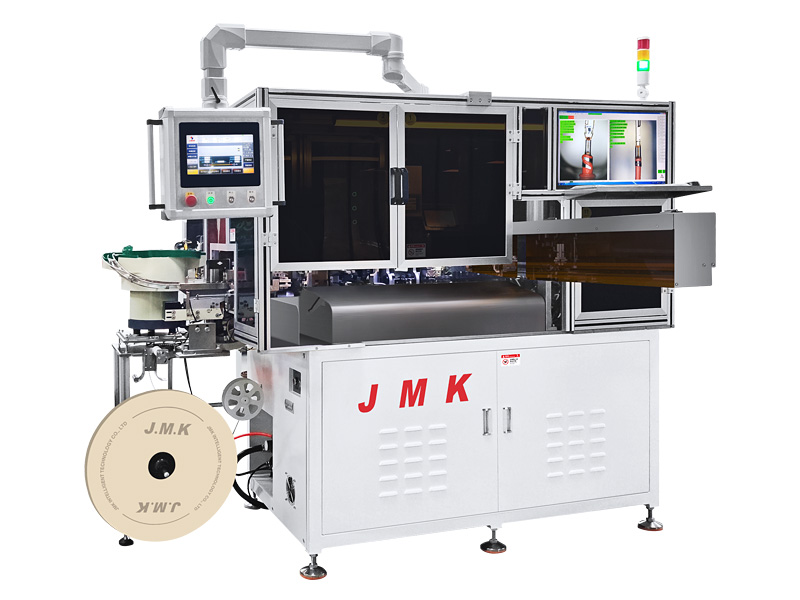

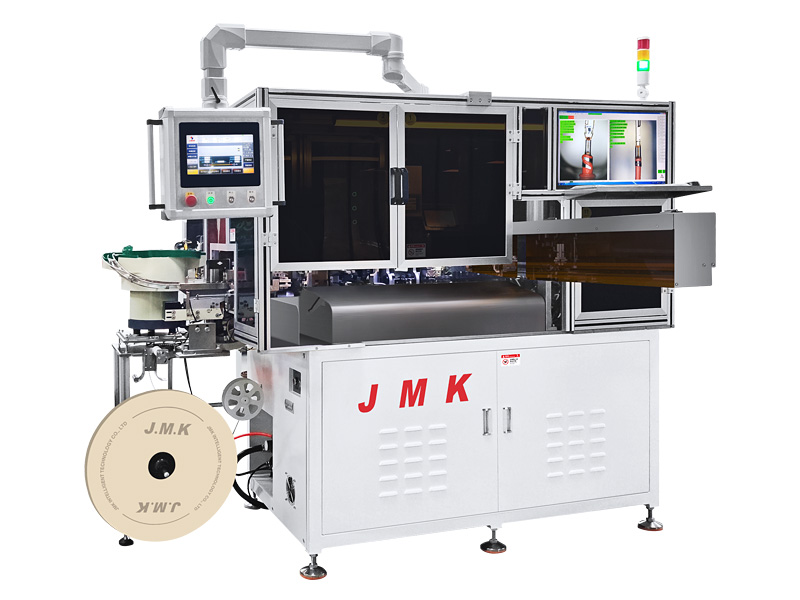

JM-601A+ Automatic single head tin dipping, waterproof plug inserting machine, supports wire cutting at fixed length, stripping at both ends, single head crimping, single head waterproof plug inserting, single head tin dipping. Can produce 45-9999mm (customizable), 1-12 wire color options (standard 6 colors), support #18 ~ #28 wire number production. Nissei Intelligent supports non-standard customization, and can also flexibly expand a number of additional functions: marking numbered tubes, threading heat-shrinkable tubes, stranded wires, and so on.

Product Feature:

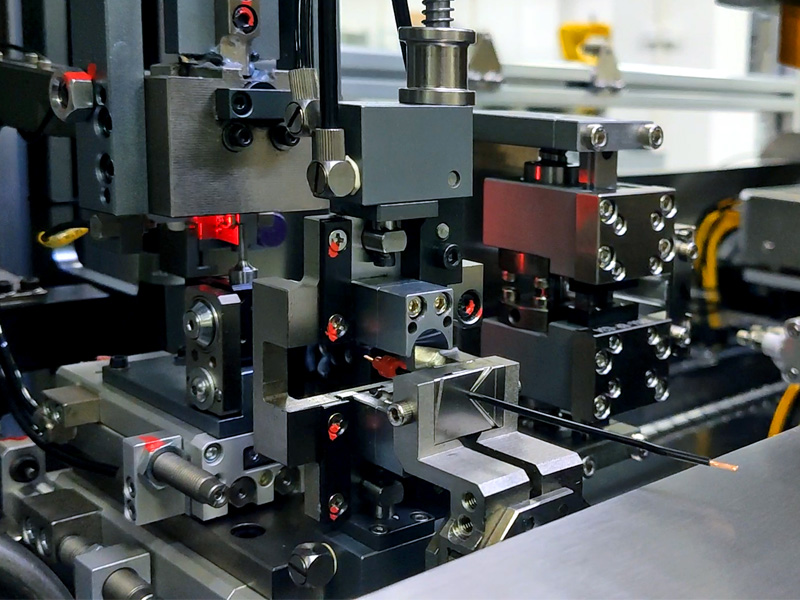

JM-601A+ can be equipped with optional pressure monitoring and CCD visual inspection system, which can display the product image and crimping force curve in real time, and carry out comparative analysis, and trigger an alarm when crimping is defective and automatically sort out the defective products. The whole process of quality control greatly saves labor costs, ensures product quality and improves production efficiency.

JM-601A

Fully automatic single head plug shell single head tinning machine

JM-601B

(Fully automatic double-end end punching machine

Technical Parameters:

Model

Single-end shell inserting machine)

Power supply

AC220V 50/60Hz 10A

Speed

Approx. 2.0 sec/strip (at shortest tangent)

Gas source

0.5MPa, approx. 170N/min

Wire color

1-8 (Standard 6 colors)

Can cut off the length

45-9999mm(customizable)

Can cut off precision

± 0.5%xL

Stripping length

Stripping length

Machinable wire diameter

Awg #18-#28 (Customizable)

Crimp ability

2T servo crimping machine x 1 set

2T servo crimping machine x 2 set

Size

W1600xD1500xH1900mm

W1700xD1500xH1900mm

Weight

About 450kg

About 500kg

Optional

CCD visual inspection; pressure monitoring; waterproof plug base station